Tech Tip

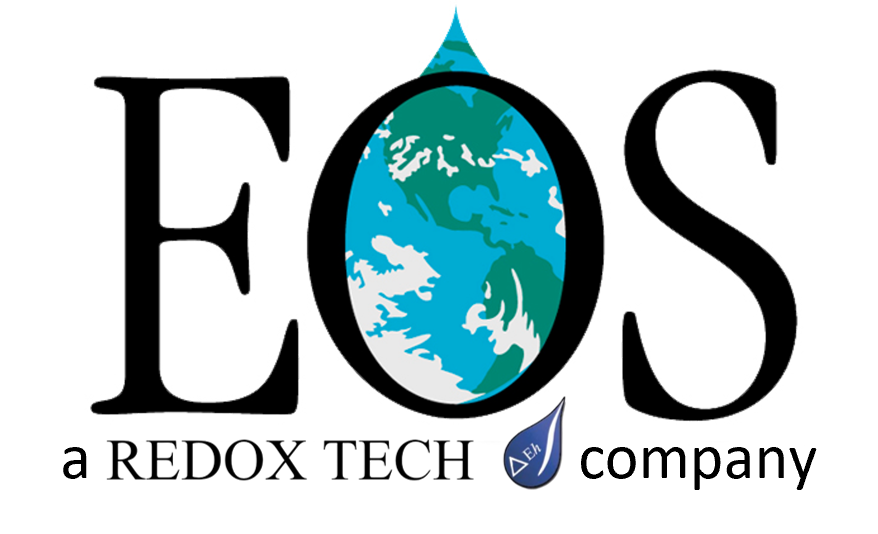

Liquid suspensions containing zero valent iron (EOS ZVI), pH buffers (CoBupHMG), magnetite, or other solid materials are often injected during in situ remediation projects. However, when the particles have a density greater than water (> 1 g cm3), there is a potential for settling at the bottom of injection wells and other flow stagnation points. One approach for limiting settling in wells is to inject the diluted suspension through a tube or ‘stringer’ that extends from the ground surface to a short distance above the bottom of the injection well. This arrangement causes the injection fluid to flow upward from the bottom of this well before flowing outward through the injection well screen. Particle settling in the bottom of the injection well is minimized by ensuring the upward flow velocity in the annulus between the stringer and the well screen is greater than the particle settling velocity (Figure 1).

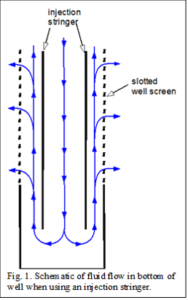

An effective injection stringer for a 2-inch slotted PVC well is shown in Figure 2.

For more info on in situ remediation, check out the articles: ZVI and Buffer Addition for pH Control on ENVIRO.wiki.